Top 5 Considerations when Switching to Electric Pizza Ovens

Converting your commercial pizza oven to an electric oven can be a daunting task for any chef or restauranteur. The gas vs electric debate is taking place in residential and commercial kitchens across the country and the world. The new clean energy legislation is having a huge impact on the conversation. These regional legislative changes and environmentally friendly trends have created an “Electrification” movement in some areas of the United States.

States and cities across the US are enacting legislation requiring new commercial kitchens to be “all-electric” to meet efficiency standards targeted at the reduction of greenhouse gas emissions and carbon-neutral footprint initiatives. Europe and many other international markets already have made the switch from gas to electric in commercial kitchens. This blog is dedicated to helping restaurant owners, design consultants, and chefs make educated choices in new construction and in renovations of existing kitchens looking to the future.

States and cities across the US are enacting legislation requiring new commercial kitchens to be “all-electric” to meet efficiency standards targeted at the reduction of greenhouse gas emissions and carbon-neutral footprint initiatives. Europe and many other international markets already have made the switch from gas to electric in commercial kitchens. This blog is dedicated to helping restaurant owners, design consultants, and chefs make educated choices in new construction and in renovations of existing kitchens looking to the future.

Once commercial brick oven operators realize that wood doesn’t contribute anything significant to the food itself, they may contemplate alternative fuel sources. Gas and electric brick oven technologies are developing fast. Commercial wood-fired brick ovens are becoming less popular as commercial brick ovens, in general, are mainstreaming. This is true not only in traditional pizzerias but across a variety of menu concepts and cuisines.

“More operators have gone to gas as a fuel source for commercial brick ovens because it’s more consistent, cleaner, and simpler to use,”

Marra Forni VP of Sales & Marketing Todd Griffith

While gas is the most largely used fuel source for commercial brick ovens, green energy legislation is driving change throughout the foodservice industry. California has established a compliance date of 2030 for all new commercial construction energy efficiency. New York City has announced all new commercial kitchens will be electric by 2025. This legislation is currently state-dependent, and each state controls specific program development for the future. With this legislation policy already in place in, there are concerns that legislators will still need to address. In California, for example, there are existing power grid challenges with rolling brownouts. The typical commercial kitchen uses 5x the energy when compared to the rest of a building housing the kitchen. The cost per kilowatt hour vs the cost for BTU is much higher. While the electric equipment costs less, the energy to operate costs more. Municipalities will need to ensure that their buildings can handle the conversion logistically. To help facilitate the conversion for operators, clean energy legislation is expected to continue to promote tax incentive programs and energy rebate programs designed to compensate for higher utility bills.

According to Todd, who is also a trained chef, here are the top 5 reasons why restaurateurs in the US should begin considering the use of electric ovens:

- State and federal legislation will eventually mandate the conversion requirement so operators should plan for the near future.

- Electric appliances do offer energy efficiency benefits and support environmental stewardship.

- There are performance benefits that electric stone hearth brick ovens offer that wood-fired and gas-fired ovens do not.

- Electric brick ovens provide more control of thermal application during the cooking process. A greater bandwidth of temperature range increases the flexibility of menu applications with more control over finished food quality.

- They typically require less skilled operators to manage – resulting in cost savings.

Proudly manufactured in the US, we are investing in the continued development of our electric brick oven solutions because we see it becoming a requirement in the future and we want to be proactive in the solutions to our partners and customers.

We offer our customers options and advantages that our competitors don’t, such as the electric version of our Neapolitan oven. We have also recently launched to commercial foodservice industry our NEW ELST Series; an electric stackable modular deck oven. This new stackable deck series will expand in size and model configuration as the ongoing development of the series continues. The electric stackable oven series addresses the following kitchen challenges:

- The kitchen floor space is still a premium. The Electric Stackable vertically integrates individual cooking decks into a common platform allowing high-volume production efficiency in a limited footprint.

- The stackable configuration is modular which means that it can grow with the operator as their business and production demand grows (stackable from 1 to 4 independent decks). No one else does that.

- Menu and performance flexibility by providing the operator with multiple cooking temperature zones in a stacked configuration ranging from 250 – 950 degrees F.

The new ELST Series electric stackable oven only requires 35 amps per deck compared to competitive brands that can use as much as 60 amps/per deck. Since this all contributes to the cost of operation, we offer substantial savings to operators on their monthly utility bills.

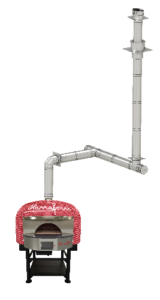

Direct venting is another lesser-known and very cost-effective solution supporting our brick oven solutions. Whether wood-fired, gas-fired, or electric, Marra Forni brick oven solutions are UL certified for use with our direct venting systems. Installed on-site by local contractors, these custom-designed turnkey systems are built based on the specifics of the restaurant or building space where the oven is placed into. These systems also ensure the oven will operate and perform at optimal efficiency.

To learn more about our commercial electric oven solutions and options, click here.